Many moulding and machining processes create boss shapes as part of the design, for aesthetics and/or function. The shapes must be correct before they leave the production line in order to complement the rest of the other parts in a production process.

Problem

The intense, directed lighting incorporated into cameras “flattens” the image, especially when the surface, including the boss shapes, are all of one material. This effectively makes any surface features invisible to the camera.

This is particularly an issue with very small work-pieces where the integrated lighting is unable to produce any contrast for the camera to image correctly.

Solution

In order for a camera to properly detect the contours on a surface the following lighting solution is needed.

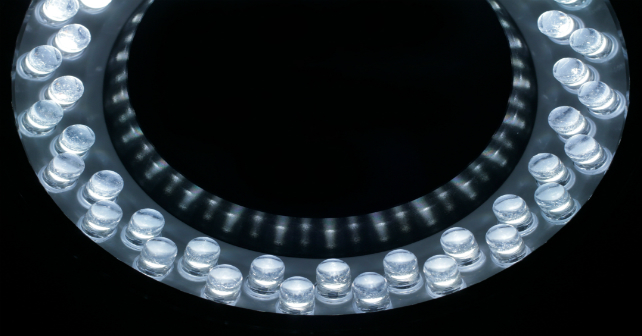

Low Angle lighting: This will light the surface from a high angle of incidence between the plane of the surface and the camera, highlighting concave and convex features. Particularly effective when coupled with LED ring light.

LED Ring light: The ring light provides diffuse light, increasing contrast between the surface and the boss features.

No Responses to “How to Set up Lighting for Working with Boss Shapes”