Laser marking is widely established in industries such as: aerospace, automotive, medical, electronics and many others.

Due to the lack of inks or tool-bits involved there is minimal (often none at all) thermal or mechanical stress on the part being marked. In this way, its non-contact nature allows it to mark materials, metal or plastic in a high-speed and permanent way.

Problem

With older products, cameras may find the OCR/OCV (optical character recognition / optical character verification) process more problematic as the integrated lighting solution may be either not sufficiently effective, or, with co-axial lighting, not suited to the application.

Solution

Depending on the shape, colour and material of the object, the best results for dealing with this application will most likely be achieved by using a setup as described here below:

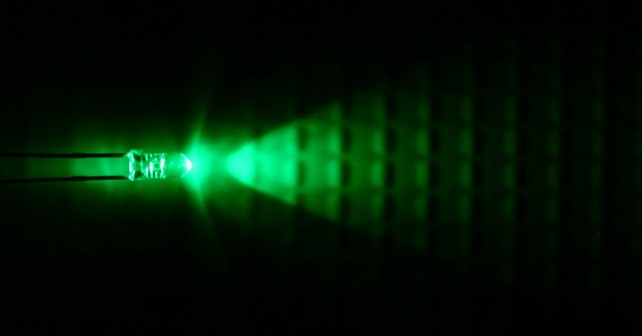

Green LEDs: By making use of the part of the spectrum to which our eyes are most attuned, the highest luminous intensity in other words, green LED light will prove the best lighting for reading laser markings; especially within ring lights.

Ring lights: A ring light provides an even light source from the edge of the field of view to the actual marking. This is enhanced by a diffusion dome.

Diffusion dome: The diffusion dome reduces reflection, giving an even light coverage to the entire marked area, allowing for a perfect contrast.

No Responses to “How to Set up Lighting for Reading Laser markings”