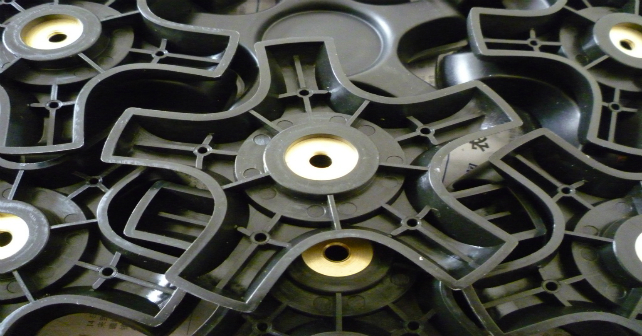

From mobile telecommunications to automotive, and medical to aerospace, having metal inserts in parts or products made from other materials is widespread and common.

The practice, though, can cause problems for machine vision systems set up for a single material process.

Problem

In order for your machine vision system to properly check that a metallic part has been correctly inserted into a work-piece made of another material, you need a light which is effective in allowing your camera to see the contrast between the materials.

Quite often the standard red, coaxial light integrated with your camera is unable to create the required contrast, rendering the metallic part invisible to the camera.

Solution

Blue, Green or White LED lights: Any colour but red will work in creating contrast between materials as the different refractive indices of the materials affect the shorter wavelengths to a greater degree.

LED Bar lights: If the shape of the work-piece dictates a square or parallel lighting zone, this can be created with bar lights set at an inclined angled.

Diffusion dome or Low Angle: For smaller parts, or those made from highly reflective materials, creating a very diffuse lighting zone will help to create the maximum contrast with minimum glare.

No Responses to “How to Set up Lighting for Detecting Metal Inserts”