Industry definition:

Machine Vision is the automatic extraction of information from digital images.

Introduction

This is intended to be a quick introduction into what machine vision is; describing its usage in industrial automation and four most common applications:

Measurement Counting Location Decoding

A little background…

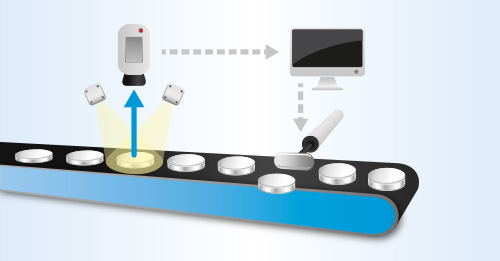

Let’s take the example of a production line as a place where machine vision is used intensively.

The elements of what we can do with machine vision build up from the situation we find there:

- A steady flow of objects on conveyor belt or production line.

- A camera.

- Proper lighting so the camera can see necessary details.

- Image capture.

- Comparison against pre-defined criteria.

They are the basis of the abilities of machine vision and give us some groundwork to go into more detail.

Why use it at all, though?

Speed

Machine vision systems can process hundreds or thousands of items / pieces of information per minute, quicker than any human operative could do the same.

Consistency

With machine vision you can be sure that every item is being processed according to the same criteria, and the same rules, every single time.

Rest periods

Machines don’t take them…

A brief history of…

Taking a quick look at its history, machine vision got its start during the ’50s but only really came into its own during the ’80s & ’90s. Since then, it’s come a long way, being used for a variety of complex and demanding tasks, including:

- high-speed inspection of complex products;

- completeness checking;

- shape inspection;

- pattern comparison;

- measurement;

- position & rotational angle detection;

- OCR ‘reading';

- Symbol reading for both 1D & 2D codes.

Next we’ll take each of the four main applications for machine vision and break them down into more detail of what they mean, and give some examples.

Measurement

In the industrial setting we can use machine vision to provide automated measurement which can be immediately checked to specified tolerances.

The gap in spark plugs:

It has to be a certain width for optimal performance of the vehicle; therefore it is a critical specification of the part. Each spark plug gap can be immediately checked against pre-defined tolerances (in the region of 0.1mm). Measuring by machine eliminates the need for a human to be there, measuring and adjusting manually. Machine vision does it more quickly and accurately.

Counting

This simply means looking for a number of parts or features on a part. This allows us to locate missing features quickly and assure that products are assembled properly.

A variation on the theme is the ability to check for the absence or presence of an item.

(features) holes in a flange:

Let’s say we have a flange with a number of holes in it, if we count the holes we find there are eight. An immediate check against specifications says that there should be eight holes, and we know the process was done properly.

Location

In regards to machine vision location means the ability to check position and orientation of a part, and then make sure that is immediately checked to specified tolerances.

bracket holes:

Machine vision can first check orientation angle. Then use that as reference point to check location of features.

spark plugs again:

The parts may be at any angle as they travel through. Machine vision takes an image, ‘straightens’ it according to pre-defined features.

Decoding

This refers to the decoding of:

- 1d symbologies such as: linear barcodes (code 128, code 39, code 93, pharmacode, interleaved 2 of 5, UPC); and stacked symbologies (pdf417, micro pdf, gs1 databar (stacked), gs1 databar (composite)).

- 2d symbologies: Data Matrix, QR, Aztec.

- OCR (optical character recognition): OCR-A, OCR-B, MICR E-13B, SEMI M12.

It is mostly used to record information as historical data.

Typically, this is to keep a record of parts which have gone through a process, track the path a part/product took through that process, use the data for immediate action, such as:

- Look at the data and sort the items based on what information is retrieved.

- Or, validate data for correctness, such as to read marked codes and match to what is expected at that point in the process on a production line.

But why use machine vision to do decoding?

- Because machine vision is not just limited to decoding, it can do the other functions in addition to the decoding, e.g. check the label make sure that it is properly aligned to the product.

- Tougher applications involving image pre-processing are also within its remit.

Example high-speed canning

Check stamp on end of unlabelled can. Matches the stamp data to the correct labelling process.

In conclusion, then…

€¦ Machine vision is a way of capturing images and enabling them to be manipulated in order to automate industrial processes quickly and reliably.

I hope you’ve enjoyed this quick primer.

No Responses to “What is Machine Vision?”